×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

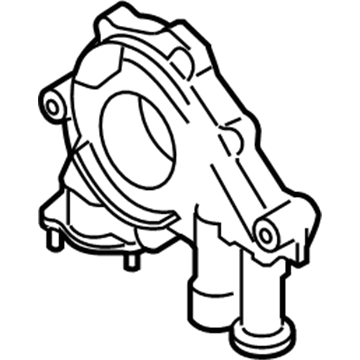

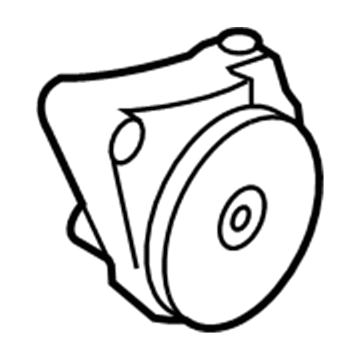

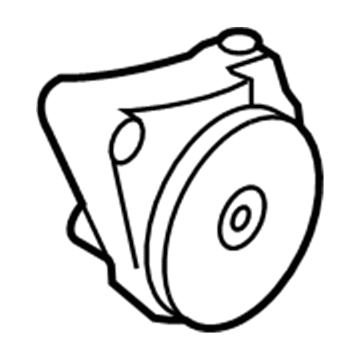

Genuine Volvo Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Oil Pumps found

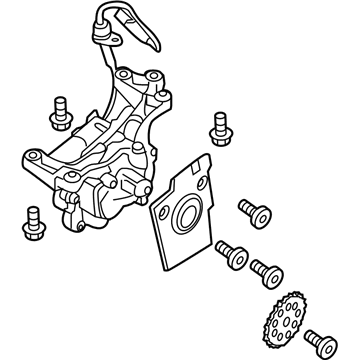

Volvo Oil Pump Part Number: 30757433

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysVolvo Oil Pump Part Number: 30758272

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysVolvo Oil Pump Part Number: 30758273

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysVolvo Oil Pump Part Number: 31670241

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 32388686

Volvo Oil Pump Part Number: 31670242

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 32388687

Volvo Oil Pump Part Number: 32298903

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Oil Pump

- Replaces: 32140128

Volvo Oil Pump Part Number: 32388687

$338.18 MSRP: $440.34You Save: $102.16 (24%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 31670242

Volvo Oil Pump Part Number: 9458427

$338.00 MSRP: $436.70You Save: $98.70 (23%)Ships in 1-2 Business DaysVolvo Oil Pump Part Number: 9458425

$339.22 MSRP: $438.26You Save: $99.04 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Pump 2508; Oil Pump

Volvo Oil Pump Part Number: 32298902

$407.36 MSRP: $530.42You Save: $123.06 (24%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 32140127

Volvo Oil Pump Part Number: 32240929

$429.19 MSRP: $554.51You Save: $125.32 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Pump

Volvo Oil Pump Part Number: 32240930

$429.19 MSRP: $554.51You Save: $125.32 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Pump

Volvo Oil Pump Part Number: 30650144

$491.92 MSRP: $640.51You Save: $148.59 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Oil Pump

Volvo Oil Pump Part Number: 9458085

$233.75 MSRP: $278.27You Save: $44.52 (16%)Ships in 1-2 Business DaysVolvo Oil Pump Part Number: 271307

$251.80 MSRP: $299.76You Save: $47.96 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oil Pump Kit; Oil Pump

Volvo Oil Pump Part Number: 1346144

$360.20 MSRP: $428.81You Save: $68.61 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Oil Pump

Volvo Oil Pump Parts and Q&A

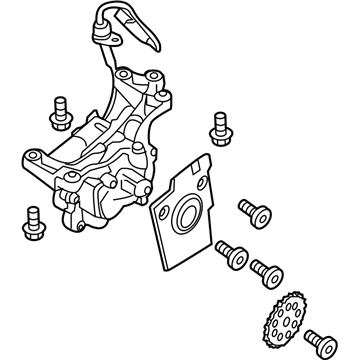

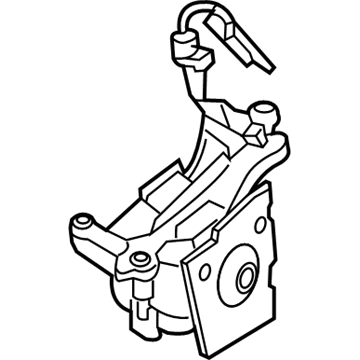

- Q: How to remove and refit the oil pump for 2.4 litre petrol engine on Volvo S40?A:To eliminate the oil pump, first perform the required operations, then take off the four bolts that hold the pump to the cylinder block. Carefully remove the pump assembly by levering behind the upper and lower parting lugs with a screwdriver, and recover the gasket. Clean the mating faces of the pump and cylinder block thoroughly, making sure that all traces of the old gasket are removed. For inspection, remove the two screws holding the pump halves together and remove the gear cover, careful of the pressure relief valve spring which may shoot out. Extract relief valve spring, plunger and pump gears and carefully lever out the crankshaft oil seal, and get a new one to refit. Clean all components well and inspect the gears, body and gear cover for wear or damage, renewing worn or damaged parts. Refit the gears to the pump body with the markings on the large gear facing upwards, lubricate the gears and then lubricate and fit the relief valve plunger and spring. Install a new O-ring seal to the pump body, fit the cover and secure with the two screws. For refitting new gasket use to attach the pump to the block guiding it with the retaining bolts and drawn into position with the crankshaft pulley nut and spacers. Once seated, bolt the retaining bolts diagonally to specified torque. Lubricate cover, crankshaft, and new oil seal and fit the seal with lips inwards using a tube or the old seal inverted and tap it into place until flush with the seal. Finally, reattach the crankshaft sprocket and pulley in reverse order of removal, and refit the timing belt.

- Q: What steps should be taken to refit the oil pump and ensure proper installation except GDI engine on Volvo V40?A:Four new copper washers need to be acquired for fitting to the pump mounting bolts during the refitting process as early models may not have any washers upon dismantling. To start, perform the required operations and remove the four bolts that hold the oil pump on the cylinder block. Carefully remove the pump assembly by prying behind the upper and the lower parting lug with a screwdriver to remove the pump and recover the gasket. Clean the mating face of the pump and cylinder block very well and make sure to remove all residues of the old gasket. Next take out the two screws holding the two halves of the pump together and take off the gear cover, ready to catch the pressure relief valve spring. Extract the relief valve spring, plunger and pump gears, carefully lever out the crankshaft oil seal, getting a new seal for refitting. Clean all the components thoroughly and check the gears, the body, and the gear cover for any signs of wear or damage. Measure the free height of the pressure relief valve spring and match it with the specified dimension, renewing it if weak or distorted as well as checking the plunger for any scoring or damage. Refit the gears to the pump body with the markings on the large gear uppermost, checking the clearance between the large gear and pump body using feeler blades and if the clearance is outside the specified limit then pump should be renewed. If satisfactory, lubricate the gears, lubricate and fit the relief valve plunger and spring. Fit a new O-ring seal to the pump body, and then put on the cover and lock it with the two screws. Using a new gasket, fit the pump to the block, placing new copper washers on the pump retaining bolts, draw the pump into place using the crankshaft pulley nut and spacers, making sure not to damage the seal in the oil pump, and not to rotate the crankshaft during fitting. After the pump is set, tighten the retaining bolts diagonally to specified torque. Lubricate the cover, crankshaft and new oil seal and install the seal with the lips inwards using a piece of tube or the old seal inverted to tap it into place until flush. Finally, refit the crankshaft sprocket and pulley in reverse of the removal procedure, and refit the timing belt.

Related Volvo Parts

Browse by Model

240 Oil Pump 244 Oil Pump 245 Oil Pump 740 Oil Pump 760 Oil Pump 780 Oil Pump 940 Oil Pump C30 Oil Pump C70 Oil Pump S40 Oil Pump S60 Cross Country Oil Pump S60 Oil Pump S70 Oil Pump S80 Oil Pump S90 Oil Pump V40 Oil Pump V50 Oil Pump V60 Cross Country Oil Pump V60 Oil Pump V70 Oil Pump V90 Cross Country Oil Pump V90 Oil Pump XC40 Oil Pump XC60 Oil Pump XC70 Oil Pump XC90 Oil Pump