×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

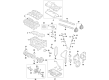

Genuine Volvo Piston Ring

Piston Ring Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Piston Rings found

Volvo Piston Rings Part Number: 275343

$26.40 MSRP: $30.92You Save: $4.52 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 275369

$31.57 MSRP: $36.97You Save: $5.40 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Ring Set Part Number: 31375565

$42.82 MSRP: $54.42You Save: $11.60 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Ring Set

Volvo Piston Rings Part Number: 271356

$46.51 MSRP: $54.45You Save: $7.94 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 31330725

$48.21 MSRP: $56.46You Save: $8.25 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 275372

$48.21 MSRP: $56.46You Save: $8.25 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Ring Set Part Number: 31493192

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Ring Set

- Replaced by: 32240866

Volvo Piston Rings Part Number: 32213048

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Ki 2506; Piston Ring Set, Piston Rings

- Replaced by: 32240866

Volvo Piston Rings Part Number: 32213696

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston, Piston Ring Set, Piston Rings

- Replaced by: 32240866

Volvo Piston Rings Part Number: 30731512

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Ring Set, Piston Rings

Volvo Piston Rings Part Number: 30731513

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 30750278

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 30750279

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 30750667

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Ring Set, Piston Rings

Volvo Piston Rings Part Number: 30750668

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 30750896

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 30750897

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 31330721

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 31359556

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Rings

Volvo Piston Rings Part Number: 31375028

$68.41 MSRP: $88.34You Save: $19.93 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Ring Kit; Piston Ring Set, Piston Rings

| Page 1 of 2 |Next >

1-20 of 28 Results

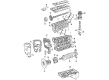

Volvo Piston Ring Parts and Q&A

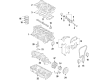

- Q: What steps should be followed to check and fit piston rings correctly on Volvo V40?A:At this stage it is assumed that the pistons have been correctly assembled to their respective connecting rods and that the piston ring to groove clearances checked. Before the rings are fitted to the pistons, it is necessary for the end gaps to be checked with the rings fitted in the cylinder bores. Lay out the piston assemblies and the new ring sets in a way that will allow the components to be kept together during and after end gap checking. Position the cylinder block on the work surface, in a side downwards position, with access to the top and bottom of the bores. Take the No 1 piston top ring and insert it in the top of the first cylinder, pushing it down the bore using the top of the piston to ensure that the ring is still square with the cylinder walls. Position the ring close to the bottom of the cylinder bore as well as the lower limit of the ring travel, keeping in mind that the top ring and the second compression ring are different, the second compression being recognizable by the step on the lower surface of the cylinder. Measure the ring gap with the help of feeler blades, repeat the process with the ring set at the end of its travel and compare the measurements with specifications. If new rings are being fitted, then it is unlikely that the end gaps will be too small or if a measurement is found to be undersize then this must be corrected in order to avoid the end gaps of the rings contacting each other during the operation of the engine, which can lead to damage to the engine. Ideally, the end gap should be fitted with new piston rings of the correct fit but, if need be, the end gaps can be increased by careful filing of the ends of the rings. It is also unlikely that the end gap will be too large, if the gaps are too large check that the correct rings for the engine and cylinder bore size are being used. Repeat the checking procedure for all rings in the first cylinder and then for the rings in the other cylinders, taking care to keep rings, pistons and cylinders matched up. Once the ring end gaps have been checked and corrected if necessary, the rings can be fitted to the pistons using the same technique as used for removal but starting with the bottom scraper ring and working up. On non-GDI engines look at the text markings on one side of the top and bottom rings, these must face upwards when fitted; the middle ring is bevelled, and the bevel must face downwards when installed. For GDI engines, we must do the following: - First fit oil scraper in bottom groove consists of three parts: First fit spacer ring and above and below it upper and lower rings, as they are identical. Avoid expanding the compression rings too far and breaking them, and always go by any instructions that came with the new piston ring sets since different manufacturers may specify different procedures. Do not confuse the first and second compression rings, they have different cross-sections. When all the rings are in place, arrange the gaps of the rings 120 degrees apart for non-GDI engines or as specified for GDI engines.

- Q: How should the piston rings be checked and fitted to ensure proper assembly on Volvo V70?A:At this stage, it is assumed, however, that the pistons have been assembled correctly to their respective connecting rods, and that the piston ring-to-groove clearances have been checked. Before the rings are fitted to the pistons, the end gaps should be checked with the rings fitted in the cylinder bores. Lay out the piston assemblies and the new ring sets, keeping the components together during and after end gap checking, with the cylinder block on its side so that it can be accessed on the top and bottom of the bores. Take the No. 1 piston top ring and insert it in the top of the first cylinder pushing it down the bore using the top of the piston to make sure it is square with the cylinder walls so that it is near the bottom of the cylinder bore at the lower limit of ring travel. The top and second compression rings are of a different type, the second ring being identified by the step on the lower surface. Measure the ring gap with feeler blades, and repeat the process with the ring at the top of its travel, and compare the measurements with the specifications. If new rings are being fitted, it is unlikely that the end gaps will be too small, however, if a measurement is found to be undersize, then it must be corrected to avoid the risk of the end of the rings contacting each other during the engine operation, which could lead to engine damage. Ideally new piston rings with the correct end gap should be fitted, but as a last resort the end gaps can be increased by carefully filing the ends of the rings with a fine file. Mount the ring in a vice using soft jaws, slip the ring over the file, moving the ring slowly to remove material from the ends, be careful because piston rings are sharp and easily broken. It is also unlikely that the gap at the end will be too large, if the gaps are too big, check that the right rings for the size of engine and cylinder bore are being used. Repeat the checking procedure for every ring in the first cylinder, and then for rings in the other cylinders, making sure that rings, pistons, and cylinders are matched up. Once the ring end gaps have been checked and corrected if necessary, the rings can be fitted to the pistons using the same technique as for removal, starting with the bottom scraper ring and working up. For petrol engines the lower oil scraper ring is a 3-part ring, so you must install the spring-like expander ring first, then the two plain rings either side. Observe the text markings on one side of the top and bottom rings which must face upwards when fitted, but the middle ring, which is bevelled, must have the bevel facing downwards. Do not expand the compression rings too far or it would break and always follow any instructions supplied with the new piston ring sets as different manufacturers may use different procedures. And avoid mixing top and second compression rings as they differ in their cross-section. When all the rings are in position, the ring gaps should be 120o apart except the 3-part oil scraper ring in which the two plain rings should be 90o apart from each other.

Related Volvo Parts

Browse by Model

240 Piston Ring 740 Piston Ring 760 Piston Ring 780 Piston Ring 940 Piston Ring C30 Piston Ring C70 Piston Ring S40 Piston Ring S60 Cross Country Piston Ring S60 Piston Ring S70 Piston Ring S80 Piston Ring S90 Piston Ring V40 Piston Ring V50 Piston Ring V60 Cross Country Piston Ring V60 Piston Ring V70 Piston Ring V90 Cross Country Piston Ring V90 Piston Ring XC40 Piston Ring XC60 Piston Ring XC70 Piston Ring XC90 Piston Ring