×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

83 Oxygen Sensors found

Volvo Oxygen Sensor Part Number: 8627750

$217.82 MSRP: $324.15You Save: $106.33 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Air / Fuel Ratio Sensor; Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30622252

$232.60 MSRP: $276.90You Save: $44.30 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30650090

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30677175

$199.85 MSRP: $237.92You Save: $38.07 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor

Volvo Oxygen Sensor, Passenger Side Part Number: 30681335

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor, Driver Side Part Number: 30713592

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor, Driver Side Part Number: 30713594

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Air/Fuel Ratio Sensor; Front Oxygen Sensor, Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30751797

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Air / Fuel Ratio Sensor; Oxygen Sensor

Volvo Oxygen Sensor, Passenger Side Part Number: 30751864

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Air/Fuel Ratio Sensor; Front Oxygen Sensor, Oxygen Sensor

Volvo Oxygen Sensor, Passenger Side Part Number: 30751865

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30756122

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30774570

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor, Driver Side Part Number: 30774651

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 30774700

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 31319665

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 31439481

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 31439622

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

Volvo Oxygen Sensor Part Number: 31480393

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

- Replaces: 31368570

Volvo Oxygen Sensor Part Number: 31480395

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

- Replaces: 31422307

Volvo Oxygen Sensor Part Number: 31480396

$252.65 MSRP: $382.80You Save: $130.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Heated Oxygen Sensor; Oxygen Sensor, Rear Oxygen Sensor

- Replaces: 31422308

| Page 1 of 5 |Next >

1-20 of 83 Results

Volvo Oxygen Sensor Parts and Q&A

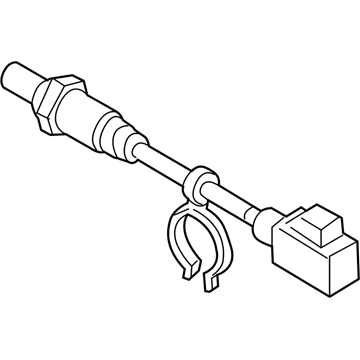

- Q: What is the function and operation of the Oxygen Sensor (02S) in vehicle exhaust systems on Volvo 940?A:The Oxygen Sensor (02S) produces an electrical voltage in response to oxygen content in exhaust gases, and is generally mounted in the exhaust manifold, and some models have internal heating for faster response. It gives a voltage between 0 and 1 volt, with lower voltages representing lean mixture and higher voltages representing rich mixture, with the ideal fuel to air ratio represented by voltages between 0.4 and 0.6 volts. Later models are equipped with two sensors for tracking the effectiveness of the catalytic converter, one tracking emissions before the converter and the other tracking emissions after the converter, giving the effectiveness of the reduction of emissions. The sensor has a specific temperature that it needs to work, and is in the OPEN LOOP mode until the engine has reached this ideal temperature, then it becomes CLOSED LOOP mode, so that the engine controller can control the air-fuel mixture depending on readings from the sensor. A Heated Oxygen Sensor (H02S) ensures optimal temperature for faster CLOSED LOOP operation where the engine controller uses information from the sensor to adjust the injector pulse width, while in OPEN LOOP the engine controller uses preprogrammed values. For testing, the H02S is disconnected and supply voltage to the heating element is checked, followed by resistance checks and continuity tests for proper function. Removing the battery by disconnecting the battery, jacking the vehicle up, carefully remove the sensor with suitable tooling, installing the sensor includes applying anti-seize compound and tightening to specified torque before reconnecting the wiring harness and lowering the vehicle.

Related Volvo Parts

Browse by Model

240 Oxygen Sensor 244 Oxygen Sensor 245 Oxygen Sensor 850 Oxygen Sensor 940 Oxygen Sensor C30 Oxygen Sensor C70 Oxygen Sensor S40 Oxygen Sensor S60 Cross Country Oxygen Sensor S60 Oxygen Sensor S70 Oxygen Sensor S80 Oxygen Sensor S90 Oxygen Sensor V40 Oxygen Sensor V50 Oxygen Sensor V60 Cross Country Oxygen Sensor V60 Oxygen Sensor V70 Oxygen Sensor V90 Cross Country Oxygen Sensor V90 Oxygen Sensor XC40 Oxygen Sensor XC60 Oxygen Sensor XC70 Oxygen Sensor XC90 Oxygen Sensor