×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

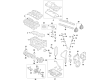

Genuine Volvo Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Crankshafts found

Volvo Crankshaft Part Number: 30757085

$599.58 MSRP: $725.88You Save: $126.30 (18%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 8250529

$600.66 MSRP: $789.19You Save: $188.53 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshaft 2601; Crankshaft

- Replaces: 8642170

Volvo Crankshaft Part Number: 30757084

$910.48 MSRP: $1102.27You Save: $191.79 (18%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 31293424

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 31430529

$891.05 MSRP: $1179.89You Save: $288.84 (25%)Ships in 1-2 Business DaysVolvo Connecting Rod Part Number: 31430531

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshaft; Connecting Rod

Volvo Crankshaft Part Number: 32267206

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 9125670

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 9465780

$575.87 MSRP: $685.56You Save: $109.69 (16%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 9465781

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 30720145

$891.05 MSRP: $1179.89You Save: $288.84 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 30757025

$891.05 MSRP: $1179.89You Save: $288.84 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 31251565

$891.05 MSRP: $1179.89You Save: $288.84 (25%)Ships in 1-2 Business DaysVolvo Connecting Rod Part Number: 31401887

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshaft; Connecting Rod

Volvo Crankshaft Part Number: 31330993

$2068.50 MSRP: $2739.02You Save: $670.52 (25%)Ships in 1-2 Business DaysVolvo Crankshaft Part Number: 9125715

$945.11 MSRP: $1144.20You Save: $199.09 (18%)Ships in 1-2 Business Days

Volvo Crankshaft Parts and Q&A

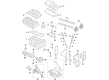

- Q: What considerations should be made regarding the crankshaft if no work is to be done on the pistons and connecting rods during engine disassembly on Volvo S70?A:If there is no work to be done on the pistons and connecting rods the removal of the cylinder head and pistons is not necessary, the pistons should be pushed up the bores to clear the crankpins. Starting out by removing the oil pump, sump, intermediate section, clutch parts and flywheel/driveplate, through to the pistons and connecting rods. Before removing the crankshaft, check the end float by temporarily refitting the intermediate section and use a dial gauge to check for the movement of the crankshaft. If the end float is out of spec, check for crankshaft thrust surfaces for wear and replace the thrust washers if there is no wear. Once you get the crankshaft out, remove the upper half main bearing shells and keep them organized. Clean the crankshaft (paraffin or suitable solvent) making sure the oil holes are free, and inspect the main and big end bearing journals for wear, scoring, pitting and cracking. Distinct metallic knocking sound while the engine is running is an indication of a big end bearing wear, in case of severe vibration and rumble main bearing. Check the bearing journal for roughness and measure the diameter of the main and big end journals with a micrometer, checking for out-of-roundness and taper. If the journals are out of tolerance, then a new crankshaft may be required, but consult an engine overhaul specialist as to regrinding options. Finally, check the oil seal contact surfaces for wear or damage, as deep grooves may necessitate a new crankshaft.

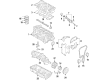

- Q: What is the process of crankshaft refitting during engine reassembly after an overhaul on Volvo V40?A:Crankshaft refitting is the first step in engine reassembly following an overhaul (assumed that the cylinder block/crankcase and crankshaft have been cleaned, inspected, and repaired as necessary). Set the cylinder block on a clean, level work surface with the crankcase up. For non-GDI engines, if still on the block, remove any old bearing shells from the block and intermediate section, and then clean out the main bearing shell seats in the crankcase and the backs of the bearing shells. Insert the selected upper shells in their appropriate position in the crankcase, making sure that the tangs engage in the recesses, and lubricate them with clean engine oil. Clean the crankshaft journals before lowering the crankshaft into position so as not to displace the bearing shells. Inject oil into the crankshaft oilways, and wipe any excess oil from the crankshaft and intermediate section mating faces. Apply a thin uniform layer of Volvo liquid gasket to the cylinder block mating face of the intermediate section, making sure to cover the entire area. Clean the main bearing shell seats in the intermediate section, insert the selected lower shells, lightly lubricate them and keep the oil away from the liquid gasket. Lay the intermediate part on the crankshaft and cylinder block, oil the threads of the retaining bolts, and tighten them according to the specified torque and sequence. Turn the crankshaft to check for resistance, making sure that there are no tight spots or binding. Check the Crankshaft Endfloat to specification if new bearing shells have been fitted. Lubricate the oil seal location, crankshaft and a new oil seal, fitting the oil seal with the lips inwards. For GDI engines, be sure to clean and dry the main bearing ladder, bearing shells, thrustwashers and crankshaft and fit upper bearing shells into the crankcase and lower shells into the main bearing ladder. Set the thrustwashers in the crankcase, oil grooves out, lubricate all bearing shells and thrustwashers and lay in the crankshaft. Check the endfloat of the crankshaft one more time and then carefully position the main bearing ladder on the crankshaft and crankcase, pointing the arrow marking towards the end of the timing belt. Lightly oil the main bearing bolt threads and heads before fitting them, re-using bolts if within specification of length. Tighten all bolts to the given Stage 1 torque setting, and then tighten them further by turning each bolt through the given degrees for Stage 2 so it makes a good smooth movements. After tightening, verify that there is no binding on the crankshaft. Make sure that mating faces of the crankshaft oil seal carrier and block are clean, apply a 3mm diameter bead of sealant to the carrier and fit it over dowels in the block. Press the carrier tightly in place and tighten the four bolts to specified torque, wiping off any excess sealant before fitting a new oil seal.

Related Volvo Parts

Browse by Model

C30 Crankshaft C70 Crankshaft S40 Crankshaft S60 Crankshaft S60 Cross Country Crankshaft S70 Crankshaft S80 Crankshaft S90 Crankshaft V40 Crankshaft V50 Crankshaft V60 Crankshaft V60 Cross Country Crankshaft V70 Crankshaft V90 Cross Country Crankshaft XC40 Crankshaft XC60 Crankshaft XC70 Crankshaft XC90 Crankshaft