×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo V50 Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

Volvo V50 Crankshaft Part Number: 9465780

$575.87 MSRP: $685.56You Save: $109.69 (16%)Ships in 1-2 Business DaysVolvo V50 Crankshaft Part Number: 9465781

$668.29 MSRP: $884.92You Save: $216.63 (25%)Ships in 1-2 Business Days

Volvo V50 Crankshaft

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Crankshaft and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V50 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V50 Crankshaft comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V50 Crankshaft Parts and Q&A

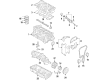

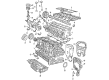

- Q: What is the process of crankshaft refitting in engine reassembly after an overhaul on Volvo V50?A:Crankshaft refitting is the first step in engine reassembly after an engine overhaul, provided that the cylinder block/crankcase and the crankshaft have been cleaned, inspected and repaired where necessary, and the piston cooling jets and valve reinstalled. Lay the cylinder block on a clean level surface with the crankcase facing up. Using an application roller with a short hair, apply an even coating of Volvo liquid gasket solution to the cylinder block mating face of the intermediate section, in order to ensure a good seal with a complete and thin layer. Clean the main bearing shell seats in the intermediate section and the backs of the bearing shells and insert the lower shells in their correct positions, pressing home on the tangs. Lightly lubricate the bearing shells being careful not to get on the liquid gasket solution and lay the intermediate section on the crankshaft and cylinder block laying the new retaining bolts and tightening them in five stages to the specified torque and angle from the outside in. For 1.6 litre engines, put the bearing shells in place, making sure that fresh shells are clean of protective grease and lubricate the shells with clean engine oil before lower the crankshaft in place. Insert thrustwashers beside the No 2 main bearing upper location ensuring oilway grooves face outwards and degrease the mating surfaces and apply a thin bead of silicone sealant to the bearing cap housing mating surface. Lubricate the lower bearing shells with clean engine oil, refit the bearing cap housing and install the retaining bolts which you tighten to the specified settings, ensuring that the crankshaft rotates freely. Repair/re-fit the piston/connecting rod assemblies, oil pump and sump, put in a new crankshaft left-hand oil seal and the flywheel, cylinder head, crankshaft sprocket and timing belt if removed. For 2.0 litre 4-cylinder engines, clean out the bearing shell seats in the main bearing caps, insert the lower shells, lubricate them and refit the caps, ensuring thrustwashers are correctly located and new rubber seals are fitted at the transmission end. Use a special tool to force the cap and seals into place using a silicone sealant to put in the corners of the main bearing cap recess. Tighten the main bearing cap bolts to specified torque readings. For 5-cylinder engines, remove old bearing shells (if still in place), clean the main bearing shell seats, insert the upper shells and lubricate them then lower the crankshaft into position. Inject oil in the oilways of the crankshaft, wipe off the extra, and apply Volvo liquid gasket solution on the cylinder block mating face of the intermediate section. Main bearing shell seats in intermediate section Clean inserting lower shells Lightly lubricate avoiding liquid gasket solution Lay down the intermediate part on the crankshaft and the cylinder block, strengthen the five stages of retaining bolts to the specified torque and the angle, and check whether there is slight resistance during the rotation of the crankshaft, and whether there are tight spots or binding points. Finally, lubricate the left hand oil seal place, crankshaft, and new oil seal fitting the seal with the lips inwards until flush.

- Q: What are the instructions for removing the crankshaft and inspecting bearings on Volvo V50?A:On 1.8 and 2.0 litre petrol engines the intermediate/main bearing section, the crankshaft and the Pistons cannot be taken out and new/exchange units are supplied with these already fitted. The following directions are specific to 2.4 litre petrol and diesel models. If no work was required on the pistons and connecting rods, the cylinder head and pistons did not need removal but, instead, the pistons in the bores should be pushed up to clear the crank pins. To remove the crankshaft, you must first remove the oil pump, the sump, the components of the clutch, and the flywheel/driveplate, after which you can remove the pistons and the connecting rods. To check the endfloat before the crankshaft is removed, the intermediate section is temporarily refitted and a dial gage is used. Push in on the crankshaft from the gauge and zero it, then push on the crankshaft in the direction of the gauge, to measure the endfloat. If it is out of specifications, examine the thrust surfaces for wear and replace thrustwashers if required. For engines 2.0 and 2.4 litre type, remove the section between the flywheel and the camshaft and lift out the crankshaft carefully. For 1.6 litre engines unscrew the small bolts holding the crankshaft bearing cap housing in place, then slacken the large retaining bolts in the reverse order of tightening. After the bolts have been removed, tap around the bearing cap housing to break the seal and raise it off, recovering the lower main bearing shells. Lift out the crankshaft and gather the left hand oil seal and store the upper main bearing shells and their corresponding lower shells. Clean the crankshaft with a suitable solvent and have the oil holes inspected to make sure they are clean, and check the main and big end bearing journals for wear, scoring or cracking. Distinct knocking means the big-end bearing is worn and severe vibration and rumble are associated with main bearing worn out. Check out roughness in bearing surface as it may need rebooking or renewal and consult engine recon specialist for more advice at under size bearings and reconditioning.