×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Timing Belts found

Volvo Timing Belt Part Number: 31104600

$59.07 MSRP: $88.04You Save: $28.97 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Timing Belt

Volvo Timing Belt Part Number: 8627484

$59.07 MSRP: $88.04You Save: $28.97 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Timing Belt

Volvo Timing Belt Part Number: 9180954

$59.07 MSRP: $88.04You Save: $28.97 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Timing Belt

Volvo Timing Belt Part Number: 9465066

$59.07 MSRP: $88.04You Save: $28.97 (33%)Ships in 1-2 Business DaysVolvo Serpentine Belt Part Number: 31401332

$80.56 MSRP: $121.05You Save: $40.49 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt; Engine Timing Belt; Belt, Serpentine Belt

Volvo Timing Belt Part Number: 32298497

$80.56 MSRP: $121.05You Save: $40.49 (34%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 31430605

Volvo Timing Belt Part Number: 30731727

$242.10 MSRP: $366.81You Save: $124.71 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt Kit; Engine Timing Belt Component Kit; Timing Belt

Volvo Timing Belt Part Number: 32213096

$242.10 MSRP: $366.81You Save: $124.71 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt Kit; Idler Pulley, Tensioner, Timing Belt

- Replaces: 31460615, 31493094, 31460035

Volvo Timing Belt Part Number: 271713

$20.92 MSRP: $31.18You Save: $10.26 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt Kit; Engine Timing Belt; Timing Belt

Volvo Timing Belt Part Number: 271747

$34.47 MSRP: $51.36You Save: $16.89 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt Kit; Engine Timing Belt; Timing Belt

Volvo Serpentine Belt Part Number: 9135553

$59.07 MSRP: $88.04You Save: $28.97 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt; Engine Timing Belt; Serpentine Belt

Volvo Timing Belt Part Number: 3507227

$55.11 MSRP: $64.53You Save: $9.42 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt; Engine Timing Belt; Timing Belt

Volvo Timing Belt Part Number: 271720

$60.84 MSRP: $71.24You Save: $10.40 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt; Engine Timing Belt; Timing Belt

Volvo Timing Belt Part Number: 271952

$66.03 MSRP: $77.96You Save: $11.93 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Timing Belt Kit; Engine Timing Belt; Timing Belt

Volvo Belt Part Number: 3547459

$85.39 MSRP: $100.82You Save: $15.43 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt; Engine Timing Belt; Timing Belt; Belt

Volvo Timing Belt Part Number: 271714

$96.78 MSRP: $114.25You Save: $17.47 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt Kit; Engine Timing Belt; Timing Belt

Volvo Timing Belt Parts and Q&A

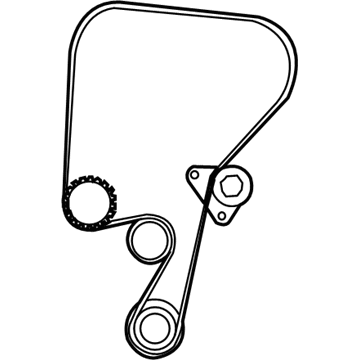

- Q: How to replace a timing belt for GDI engine on Volvo V40?A:Before beginning this procedure, it is advisable to get a sprocket locking tool to hold the camshaft sprockets against the tension of the valve springs when the timing belt is removed; however, it is possible to make a simpler tool with an assistant to hold it. Also required will be an assistant to assist in moving the engine on its mountings because of the lack of clearance for several of the bolts, especially the engine right-hand mounting. An engine support bar or hoist is advisable since the engine has to be raised or lowered on its mountings, which are still available, at various points. Begin by disconnecting the battery negative lead and removing the engine top cover panel which is bolted by six bolts. Disconnect the engine speed sensor wiring plug and untwist the wiring harness to the inlet manifold bracket. Remove the auxiliary drivebelts and undo the four bolts to remove the timing belt upper cover. Unbolt the alternator drivebelt tensioner and its mounting bracket and note the difficulty getting one of the bolts. Release fasteners that hold the arch liner in place on the wheel for access to the crankshaft pulley, preferably removing the crankshaft pulley as well as the front portion of the engine beneath shield. Hold the crankshaft pulley stationary, slacken its center retaining nut using a holding tool or jamming the flywheel ring gear, if necessary. Remove the pulley and belt guard plate and place an engine hoist or support bar and attach to the engine right hand lifting eyelet. Unbolt the brace between the power steering pump and the engine mounting bracket and unbolt the coolant pipe support bracket for additional clearance. Remove the five bolts that hold on the timing belt lower cover and pull it downwards. Remove the power steering fluid reservoir without disconnecting the hoses, and then remove the upper section of the engine mounting. Loosen the remaining bolts holding the bottom portion of the engine mounting, and try raising and lowering the engine to get enough room for the bolts that could not be removed earlier. Timing belt: If it is to be re-used, mark the fitted position of the timing belt on the camshaft sprockets and align the timing marks on the camshaft and crankshaft sprockets. A special tool is used to lock the camshaft sprockets in position before the timing belt is removed, so that the least amount of movement occurs in the sprockets. Check the tensioner and idler pulleys for roughness or shake and renew these if they do not seem to be OK and check the timing belt for wear or contamination and replace the timing belt if there is any doubt about its condition. Renew the tensioner assembly if there are signs of oil leaks or does not properly compress. Before refitting the timing belt, compress and lock the tensioner plunger, clean the mating surfaces and fix the tensioner to the engine. Make sure the camshaft sprockets are on the right alignment, and turn the crankshaft sprocket anti-clockwise by half a tooth before slipping the belt over the sprockets. Check the alignment of the sprocket marks, press down on the tensioner pulley lever arm and tighten the tensioner pulley centre bolt. Recheck the alignment and rotate the engine about a quarter turn anti-clockwise and adjust the tensioner pulley to take up the slack in the belt. Turn the engine clockwise 2 full turns to be sure to make the alignment marks again line up, and take off the locking pin from the tensioner. Leave the engine in place for two minutes before you try to refit the locking pin in place. Refit the engine mounting bracket, making sure all bolts are tightened to the specific torque and fit the upper section of the engine mounting loosely and adjust the height of the engine for alignment. Refit timing belt lower cover and coolant pipe bracket and fit the timing belt guard plate and refit crankshaft pulley. Tighten pulley bolt to specified torque, refit alternator drivebelt adjuster bracket and tension drivebelts. Refit the roadwheel, lower the car and tighten the wheel nuts diagonally. Reconnect the power steering fluid reservoir and engine speed sensor wiring, reconnect the battery negative lead and refit the engine top cover panel.

- Q: How to remove and replace the timing belt for petrol engines on Volvo V70?A:To remove the timing belt start by disconnecting the battery negative lead and remove the engine compartment cross stay by undoing the bolts and nuts. Next, remove the auxiliary drivebelt, and remove the timing belt inner/upper cover by removing the Torx screws and spring clips. If it would work, unbolt the turbocharger intake ducting and remove the spark plug cover. Move the power steering fluid reservoir out of the way without disconnecting the hoses and make sure to keep it upright. Reach up and disconnect the coolant level sensor wiring by lifting the cooling system expansion tank out. Remove the timing belt front cover by undoing the bolt in the centre of the cover and lifting the cover to release the clips. Jack up the car at the front, remove the right hand roadwheel at the front and fold forward the inside of the wheel arch liner to get at the crankshaft pulley. Temporarily install the timing belt inner upper cover, and then turn the crankshaft in a clockwise direction until the timing marks are aligned. Remove the crankshaft pulley, which is held in place by four bolts and a central nut, using a home-made tool to hold it in place while you loosen the nut. For models up to 2006, use a 6 mm Allen key to loosen the timing belt tensioner and turn it to take tension off it. For models from 2006, you will need to slightly loosen the tensioner centre bolt and lock it in position. If reusing a belt, mark the running direction of the belt, and then slip the belt off of the sprockets and idler pulleys. Check the idler pulley for any roughness and check the timing belt for wear or any damage and renew if required. If you have over 36,000 miles on the existing belt, replace it regardless of its condition. Check for oil or coolant leaks, and check for failure of the coolant pump. Renew the tensioner assembly if there is any doubt about the condition of the item. Before refitting the timing belt, make sure that the sprockets are in place. Refit the belt tensioner, making sure to place it in the proper position, and slip the belt over the crankshaft sprocket and other parts and hold it taut. Recheck the alignment of the sprocket marks then adjust the tensioner as required on models made up to 2006 or remove the locking pin on later models. Once you have made sure that you can align the timing marks again, refit the crankshaft pulley and have all bolts tightened to specified torque. Finally, secure the wheel arch liner, refit the roadwheel and bring the car down, tightening the wheel bolts in a diagonal order before fitting all other components removed to get at them.

Related Volvo Parts

Browse by Model

240 Timing Belt 244 Timing Belt 245 Timing Belt 740 Timing Belt 760 Timing Belt 780 Timing Belt 850 Timing Belt 940 Timing Belt 960 Timing Belt C30 Timing Belt C70 Timing Belt S40 Timing Belt S60 Cross Country Timing Belt S60 Timing Belt S70 Timing Belt S80 Timing Belt S90 Timing Belt V40 Timing Belt V50 Timing Belt V60 Cross Country Timing Belt V60 Timing Belt V70 Timing Belt V90 Cross Country Timing Belt V90 Timing Belt XC40 Timing Belt XC60 Timing Belt XC70 Timing Belt XC90 Timing Belt