×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

46 Drive Belts found

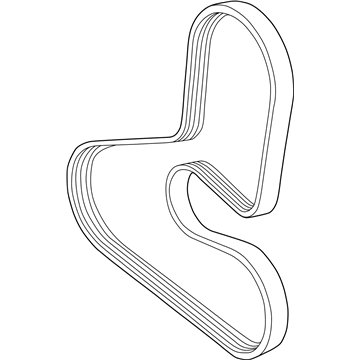

Volvo Serpentine Belt Part Number: 30777530

$31.72 MSRP: $47.28You Save: $15.56 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; A/C Belt, Alternator Belt, Serpentine Belt

Volvo Serpentine Belt Part Number: 30777531

$31.72 MSRP: $47.28You Save: $15.56 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt

Volvo Serpentine Belt Part Number: 9458469

$28.34 MSRP: $48.39You Save: $20.05 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 30731811

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 30757007

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 31251046

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 31430015

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

- Replaces: 31316095

Volvo Serpentine Belt Part Number: 31430016

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

- Replaces: 31401813

Volvo Serpentine Belt Part Number: 8653617

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 9487315

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 30777431

$43.85 MSRP: $65.35You Save: $21.50 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo A/C Belt Part Number: 31325042

$46.65 MSRP: $69.52You Save: $22.87 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Serpentine Belt; Drive Belt; A/C Belt

Volvo A/C Belt Part Number: 31430733

$46.65 MSRP: $69.52You Save: $22.87 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Serpentine Belt; Drive Belt; A/C Belt, Water Pump Belt

Volvo Serpentine Belt Part Number: 32325010

$49.46 MSRP: $73.70You Save: $24.24 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt, Water Pump Belt

- Replaces: 32146438, 31430737

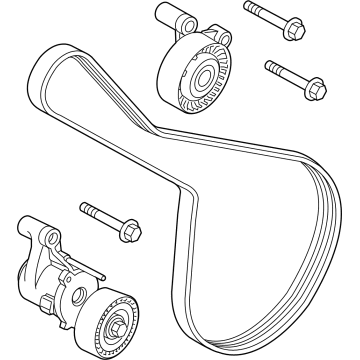

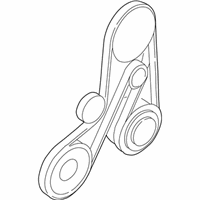

Volvo Serpentine Belt Part Number: 31480362

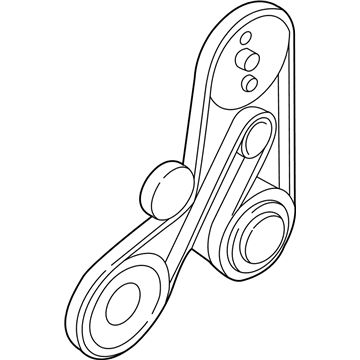

$127.72 MSRP: $191.90You Save: $64.18 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt Set; Drive Belt; Belt, Serpentine Belt

- Replaces: 31430706

Volvo Serpentine Belt Part Number: 31480409

$157.32 MSRP: $236.40You Save: $79.08 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt Set; Drive Belt; Belt, Serpentine Belt

- Replaces: 31401460

Volvo Serpentine Belt Part Number: 32213657

$170.28 MSRP: $255.87You Save: $85.59 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt Set; Drive Belt; Belt, Serpentine Belt

- Replaces: 31401459, 31480360, 31460675, 31480093, 31430219

Volvo Serpentine Belt Part Number: 30731808

$31.72 MSRP: $47.28You Save: $15.56 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Drive Belt, Serpentine Belt

Volvo Serpentine Belt Part Number: 30731809

$31.72 MSRP: $47.28You Save: $15.56 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

Volvo Serpentine Belt Part Number: 9458376

Product Specifications- Other Name: Belt; Drive Belt; Serpentine Belt

| Page 1 of 3 |Next >

1-20 of 46 Results

Volvo Drive Belt Parts and Q&A

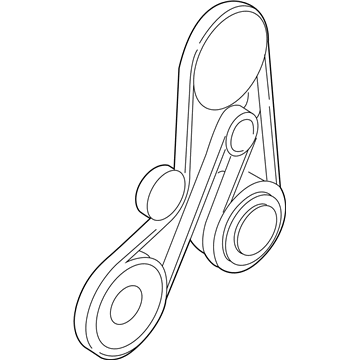

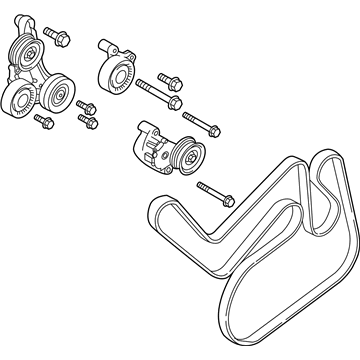

- Q: How should drive belts be inspected and maintained on Volvo 740?A:Inspect the bells for signs of glazing or cracking, a glazed belt will be perfectly smooth from slippage, a good bell will have a slight texture of fabric. Cracks will usually start at the inside edge of the belt and spread outward, thus requiring immediate replacement of any worn or damaged drive belts. As a preventive measure in service, it is advisable to replace all the drive belts at the same time. To check the tension of the drive belts depress a flat part of the belt between two components, proper tension is indicated by a movement of 1/4-3/8 of an inch otherwise adjustment or replacement is required if the belt is old and stretched. For V-belts, before making an adjustment, check the V-belt, loosen the adjustment bolts, and turn the accessory to increase the belt tension, and check the tensions when supporting the accessory. If the tension is satisfactory tighten adjusting bolts and recheck. In contrast, serpentine belts use an automatic drive belt tensioner, and therefore don't need any adjustment. For removal and installation of V-belts, disconnect the negative battery cable, loosen the mounting and adjusting bolts, and move the accessory to its loosest position, before removing the old belt. Check Pulleys Check for dirt and install the new belt with gentle pressure in the direction of rotation, adjust the tension, retighten the bolts, and reconnect the battery cable. For serpentine belts, get the negative battery cable disconnected and use a suitable tool to rotate the tensioner and release tension or remove the belt and note how it routs to the location of the new belt, then place the new belt around the accessories and crankshaft and make sure that the belt has the correct rout and has the correct tension then reattach the battery cable.

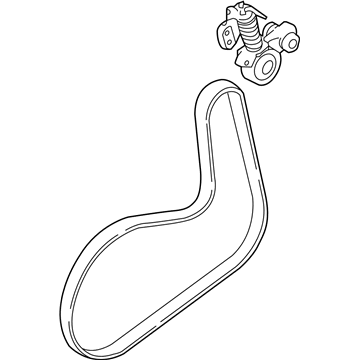

- Q: How is the correct drive belt tension maintained and what steps are involved in replacing the drive belt on Volvo V40?A:The correct drive belt tension is constantly maintained by an automatic adjuster and tensioner assembly, which is bolted to the front of the engine and has a spring-loaded idler pulley. To reach the power steering pump pulley, the metal guard from the pump casing needs to be unbolted and removed. The tensioner idler pulley must be released to allow for the removal of the drive belt; this is done by fitting a ring spanner to the center bolt of the idler pulley and rotating the spanner in a clockwise direction until the locking holes on the tensioner body become aligned. Limited access may necessitate supporting the front of the car on axle stands and removal of the left-hand front roadwheel followed by the wheel arch liner to get at it. Once the pulley has been held in the released position, using a metal rod or drill bit, the drive belt can be slipped off of all of the pulleys. The new belt should be placed over each pulley ensuring correct seating and the tensioner should be gradually released (after applying pressure with the spanner). The tensioner mechanism will automatically take up any free play and the engine is to be rotated to ensure that the belt is in location. After that, the metal guard over the power steering pump pulley should be reattached and securely tightened. For the GDI engine, the right-hand front roadwheel nuts should be loosened, the car jacked up, and the wheel removed for better access. The drive belt tension may be relieved by loosening the nut at the center of the tensioner pulley and turning the adjuster bolt. The new drive belt should be fitted around the pulleys and the tension should be set to obtain a total deflection of around 10 to 12 mm. The alternator drive belt can be removed after the power steering pump/air conditioning compressor drive belt and the new drive belt should be fitted and tensioned in the same way, and the tension checked and adjusted according to needs. Finally, the alternator pivot bolt nut should be tightened, the other drive belt refitted, and the engine undershields replaced before lowering the car.

Related Volvo Parts

Browse by Model

240 Drive Belt 244 Drive Belt 245 Drive Belt 740 Drive Belt 760 Drive Belt 780 Drive Belt 850 Drive Belt 940 Drive Belt 960 Drive Belt C30 Drive Belt C70 Drive Belt S40 Drive Belt S60 Cross Country Drive Belt S60 Drive Belt S70 Drive Belt S80 Drive Belt S90 Drive Belt V40 Drive Belt V50 Drive Belt V60 Cross Country Drive Belt V60 Drive Belt V70 Drive Belt V90 Cross Country Drive Belt V90 Drive Belt XC40 Drive Belt XC60 Drive Belt XC70 Drive Belt XC90 Drive Belt