×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo V40 Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Drive Belt found

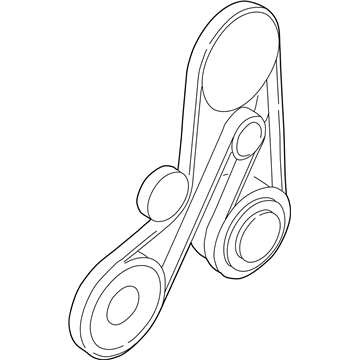

Volvo V40 Serpentine Belt Part Number: 30731808

$31.72 MSRP: $47.28You Save: $15.56 (33%)Ships in 1-2 Business Days

Volvo V40 Drive Belt

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Drive Belt and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V40 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V40 Drive Belt comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V40 Drive Belt Parts and Q&A

- Q: How does the drive belt transmit power and what steps should be taken to inspect it on Volvo V40?A:The drive belt runs from the crankshaft pulley to the alternator, power steering pump and air conditioning compressor, with models with the GDI engine having two separate belts. To check the drive belt, make sure the engine and ignition are off, open and support the bonnet and locate the drive belt at the end of the crankshaft pulley on the right-hand side of the engine. For turbo models, remove the engine right-hand cover, and the cover over the right headlight. Use an inspection light or small electric torch to examine all the drive belt lengthwise for cracks, separation, torn or worn ribs, fraying and glazing. Both sides of the drive belt should be inspected by twisting the drive belt to inspect the underside and feeling for problems where there is limited visibility. If there are any doubts of the condition of the drive belt, it should be renewed. To aid inspection, it may be helpful to jack up the car and support the front of the car on axle stands so the crankshaft pulley can be accessed once the roadwheel has been removed and the inner wheel arch panel folded back. For models without the GDI engine, depress the belt in the middle of the longest run and make sure the automatic belt tensioner is able to move freely and comes back when pressure is removed; replace the automatic belt tensioner if it is questionable in condition. In GDI engine models both drive belts have manual tensioners, which do not normally need adjustment in the course of normal service. To check the tension, press down on the top run of each belt midway between the pulleys ensuring a total belt deflection is between 10 and 12 mm, if it is outside this range then adjustments are necessary.