×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

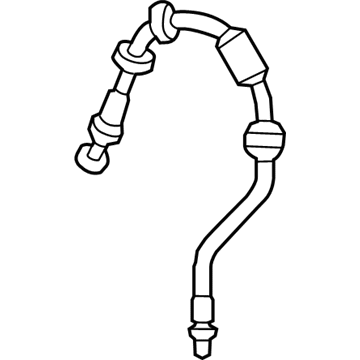

Genuine Volvo Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

66 Brake Hoses found

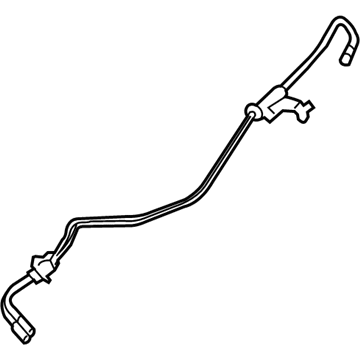

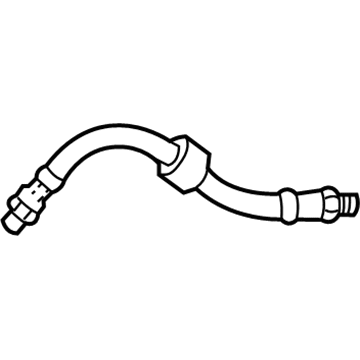

Volvo Flex Hose Part Number: 32221979

$43.44 MSRP: $64.75You Save: $21.31 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Brake Hydraulic Hose; Flex Hose

- Replaces: 30681723

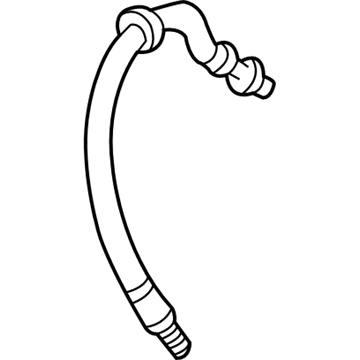

Volvo Flex Hose Part Number: 32221980

$43.44 MSRP: $64.75You Save: $21.31 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Brake Hydraulic Hose; Flex Hose

- Replaces: 30681724

Volvo Flex Hose Part Number: 32246090

$44.91 MSRP: $66.92You Save: $22.01 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31261882

Volvo Flex Hose Part Number: 32246091

$44.91 MSRP: $66.92You Save: $22.01 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31305075, 31274774

Volvo Flex Hose Part Number: 32246093

$44.91 MSRP: $66.92You Save: $22.01 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31305080

Volvo Flex Hose Part Number: 32246101

$44.91 MSRP: $66.92You Save: $22.01 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31341938, 31305077

Volvo Flex Hose Part Number: 32246084

$52.19 MSRP: $76.40You Save: $24.21 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose 2511; Brake Hydraulic Hose; Brake Hose, Flex Hose

- Replaces: 30778919

Volvo Flex Hose Part Number: 32246083

$56.49 MSRP: $84.19You Save: $27.70 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Brake Hydraulic Hose; Flex Hose

- Replaces: 30648980

Volvo Flex Hose, Driver Side Part Number: 32221999

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31362778

Volvo Flex Hose, Passenger Side Part Number: 32246000

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31471205, 32298058

Volvo Flex Hose, Driver Side Part Number: 32246001

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31362776, 31678088, 32221397

Volvo Flex Hose, Passenger Side Part Number: 32246002

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31678087, 31362777, 32221398

Volvo Flex Hose, Driver Side Part Number: 32246003

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31658933, 32221399, 31400877

Volvo Flex Hose, Driver Side Part Number: 32246005

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31678085, 31400442, 32221401

Volvo Flex Hose, Passenger Side Part Number: 32246006

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31400443, 31678086, 32221402

Volvo Flex Hose, Driver Side Part Number: 32246007

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose 2508; Brake Hose, Flex Hose

- Replaced by: 32302519

Volvo Flex Hose, Passenger Side Part Number: 32246008

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose 2509; Brake Hose, Flex Hose

- Replaced by: 32302520

Volvo Flex Hose Part Number: 32246089

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

- Replaces: 31257711

Volvo Flex Hose, Driver Side Part Number: 32246625

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

Volvo Flex Hose, Passenger Side Part Number: 32246626

$57.94 MSRP: $86.34You Save: $28.40 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose; Flex Hose

| Page 1 of 4 |Next >

1-20 of 66 Results

Volvo Brake Hose Parts and Q&A

- Q: How should metal lines and rubber brake hoses be checked and maintained to ensure proper braking performance on Volvo 740?A:Metal lines and rubber brake hoses should be inspected regularly for leaks and exterior damage, because metal lines can be easily crushed and kinked beneath the vehicle, which will limit the flow of fluid and affect braking. Rubber hoses should be inspected for cracking or scraping as such damage can cause weak spots which can fail under pressure. When lines are removed or disconnected, extreme cleanliness is essential; all of the joints and connections should be cleaned prior to disassembly and lines and ports should be plugged after opening. Note: New lines and hoses should be flushed with brake fluid before installation to avoid contamination. To remove a line or hose, disconnect the negative battery cable, jack up and support the vehicle, and eliminate as many wheel and tire assemblies as necessary for accessibility. Clean the area around the joints, place a catch pan underneath, and to disconnect the hose or line use two wrenches to dissociate the connection, paying attention to use a back-up wrench so as not to damage the fittings. Disconnect any retaining clips or brackets and take the line off, being careful to tape or plug any remaining clips and ports if the brake system is going to be open for an extended period of time. For installation, begin your new line or hose at the end that is furthest away from the master cylinder, having both of your fittings well-threaded and not rubbing to any other part, with 1/2 inch minimum space from the steering column and moving parts. Reinstall any protective shielding or insulators, tighten any fitting using two wrenches and reinstall any retaining clips or brackets. If applicable, reinstall the wheel and tire assemblies, lower the vehicle, refill the brake master cylinder reservoir with clean brake fluid that meets DOT 3 specifications, properly bleed the brake system and reconnect the negative battery cable.

Related Volvo Parts

Browse by Model

240 Brake Hose 244 Brake Hose 245 Brake Hose 740 Brake Hose 760 Brake Hose 780 Brake Hose 850 Brake Hose 940 Brake Hose 960 Brake Hose C30 Brake Hose C40 Recharge Brake Hose C70 Brake Hose S40 Brake Hose S60 Brake Hose S60 Cross Country Brake Hose S70 Brake Hose S80 Brake Hose S90 Brake Hose V40 Brake Hose V50 Brake Hose V60 Brake Hose V60 Cross Country Brake Hose V70 Brake Hose V90 Brake Hose V90 Cross Country Brake Hose XC40 Brake Hose XC40 Recharge Brake Hose XC60 Brake Hose XC70 Brake Hose XC90 Brake Hose