×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Crankshaft Position Sensors found

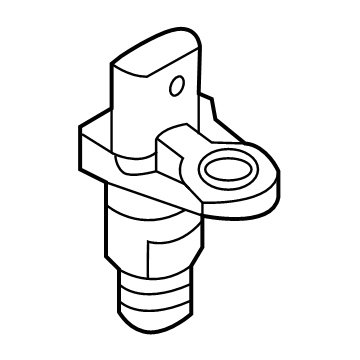

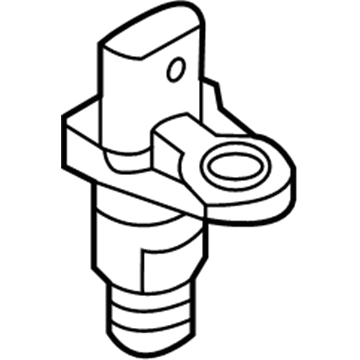

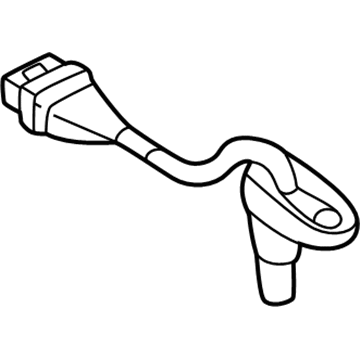

Volvo Crankshaft Position Sensor Part Number: 30668635

$75.19 MSRP: $97.09You Save: $21.90 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshaft Position Sensor, Crankshaft Sensor, ECM

Volvo Crankshaft Position Sensor Part Number: 31303937

$75.19 MSRP: $97.09You Save: $21.90 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Crankshaft Position Sensor; Crankshaft Sensor; Crankshaft Position Sensor, Crankshaft Sensor

Volvo Crankshaft Position Sensor Part Number: 31331753

$75.19 MSRP: $97.09You Save: $21.90 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Crankshaft Position Sensor; Crankshaft Sensor; Crankshaft Position Sensor, Crankshaft Sensor

Volvo Crankshaft Position Sensor Part Number: 31342468

$75.19 MSRP: $97.09You Save: $21.90 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Crankshaft Position Sensor; Crankshaft Position Sensor, Crankshaft Sensor, ECM

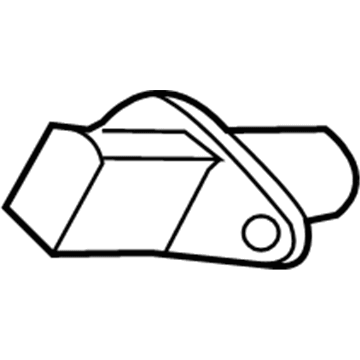

Volvo Crankshaft Position Sensor Part Number: 1270603

Product Specifications- Other Name: Engine Crankshaft Position Sensor; Crankshaft Position Sensor, Crankshaft Sensor

Volvo Crankshaft Position Sensor Part Number: 3547699

Product Specifications- Other Name: Engine Crankshaft Position Sensor

Volvo Crankshaft Position Sensor Parts and Q&A

- Q: What is the significance of the Crankshaft Position Sensor in engine operation on Volvo 960?A:The Crankshaft Position (CKP) Sensor. Aka, RPM or Impulse Sensor, the Crankshaft position sensor is necessary to determine the engine's speed and Top Dead Center (TDC) to ensure the precise timing of the ignition system. Positioned at the back of the engine block above the flywheel, this transmits the engine speed to the fuel control unit, which is very important for engine start-up. In case of vehicles with LH Jetronic and EZK Ignition Systems, the pulsewheel displays 60 markings for CKP sensor and 58 drilled holes provide information to the ignition control unit and 2 markings at 90 degrees Before Top Dead Center (BTDC) for cylinders No. 1 and 4 for control ignition timing without changing their timing. Similarly, Regina Engine Control and REX-1 Ignition Systems have 44 markings, the same thing for the ignition timing configuration. In Motronic Engine Control Systems the flywheel has holes on the top surface that induce voltage in the CKP sensor which generates an A/C signal with a frequency depending upon the number of holes passing per second; the voltage varies from 0.1 to 55 volt DC depending upon engine speed and temperature; a longer hole is provided at 90 TDC for cylinder 1 to allow the ECM to calculate camshaft position. For testing, unhook the negative battery cable, unhook the sensor connector and test the resistance across the two sensor terminals, it should be between 200-500 ohms, if not it is out of range, the sensor needs replacement. For removal and installation, remove the negative battery cable, access the sensor by removing the required components, unplug the connector and remove the retaining screws to remove the sensor. To install, install the sensor, tighten the bolts, reconnect the connector, reinsert any parts removed, and reconnect the negative battery cable.

Related Volvo Parts

Browse by Model

850 Crankshaft Position Sensor 960 Crankshaft Position Sensor C70 Crankshaft Position Sensor S40 Crankshaft Position Sensor S60 Crankshaft Position Sensor S60 Cross Country Crankshaft Position Sensor S70 Crankshaft Position Sensor S80 Crankshaft Position Sensor S90 Crankshaft Position Sensor V40 Crankshaft Position Sensor V60 Crankshaft Position Sensor V60 Cross Country Crankshaft Position Sensor V70 Crankshaft Position Sensor V90 Crankshaft Position Sensor V90 Cross Country Crankshaft Position Sensor XC40 Crankshaft Position Sensor XC60 Crankshaft Position Sensor XC70 Crankshaft Position Sensor XC90 Crankshaft Position Sensor