×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo V50 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Oil Pan found

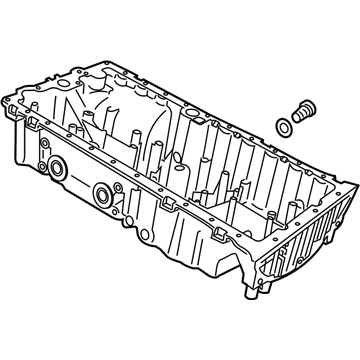

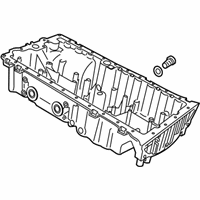

Volvo V50 Oil Pan Part Number: 30777739

$566.35 MSRP: $737.43You Save: $171.08 (24%)Ships in 1-2 Business Days

Volvo V50 Oil Pan

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Oil Pan and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V50 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V50 Oil Pan comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V50 Oil Pan Parts and Q&A

- Q: What steps should be taken to achieve an oil-tight joint on the Oil Pan during reassembly for 2.0 litre 4-cylinder diesel engine on Volvo V50?A:The complete procedure must be followed to ensure that the mating surfaces are cleaned up to prepare for an oil-tight joint when reassembled. Begin by applying the handbrake, jacking up the front end of the vehicle and standing it on axle stands. Remove the engine undershield by unscrewing the 7 Torx screws. Drain the engine oil, clean and refit the drain plug and tighten it to the specified torque; it is strongly recommended to renew the oil filter element. Pull the plastic cover on top of the engine upwards, then slacken the hose clamps, undo the bracket bolt and take the charge air pipe from the underside of the engine. Next, get rid of the air conditioning compressor drivebelt, undo the mounting bolts, and suspend the compressor out of the way without disconnecting the refrigerant pipes, using the radiator crossmember as a suspension point. Progressively unscrew the oil pan retaining Allen bolts, including the 2 securing the oil pan to the transmission housing and break the joint carefully with a putty knife, taking care not to damage the sealing surfaces. For reassembly, clean and degrease thoroughly the mating surfaces of the cylinder block/crankcase and oil pan, and remove all traces of sealant, and wipe out the oil pan and interior of the engine with a clean rag. Apply a 3mm thick bead of sealant to the oil pan flange ensuring it is around the inside edge of the bolt holes without going inside them and refit the oil pan within 5 minutes of applying the sealant. Fit the retaining bolts, tightening them by hand to start with, then tighten the 2 bolts which hold the oil pan to the transmission casing to the specified torque, followed by the rest gradually and evenly to the specified torque. Now lower the car to the ground, refill the engine with oil and install a new oil filter, if it was removed. It is recommended to wait at least 2 hours before starting the car in order to allow the sealant to cure completely.