×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine 2005 Volvo V50 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Oil Pan found

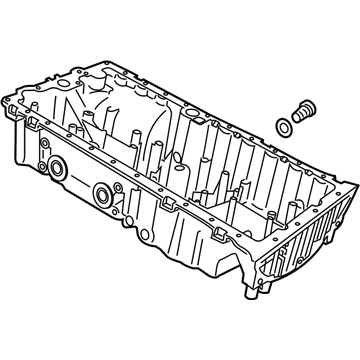

2005 Volvo V50 Oil Pan Part Number: 30777739

$566.35 MSRP: $737.43You Save: $171.08 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Engine Oil Pan

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30777739

- Warranty: This genuine part is guaranteed by Volvo's factory warranty.

2005 Volvo V50 Oil Pan Parts and Q&A

- Q: How to remove and refit the oil pan for 2.0 and 2.4 litre 5-cylinder diesel engine on 2005 Volvo V50?A: To remove the engine oil pan, first jack up the front of the vehicle and support it securely on axle stands. Next, undo the screws to remove the engine undershield, then drain the engine oil. Remove the auxiliary drive belt and undo the three bolts to move the air conditioning compressor aside, securing it with wire. Pull the oil level dipstick guide tube from the oil pan after undoing the bolt/nut, then disconnect the wiring plug, undo three bolts, and remove the oil level sensor from the oil pan. If an oil cooler is fitted, undo the four bolts securing it to the oil pan and pull it to the rear, being prepared for oil spillage. Remove the charge air pipe below the oil pan by undoing the clips and the bolt securing the mounting bracket. Slacken the bolts securing the oil pan, removing all but one bolt in each corner. Gently tap the sides and ends of the oil pan until it releases, then undo the remaining bolts and remove the oil pan, discarding the O-rings at the right-hand end/front edge. For refitting, clean the contact faces of the oil pan and block, apply a thin and even layer of Volvo sealant to the oil pan mating face, and position new O-ring seals on the engine block face, ensuring the oil pan is refitted within five minutes of applying the sealant. Refit the oil pan casing and retaining bolts, tightening them finger-tight initially, noting that the three longest bolts go to the oil pump end and the four slightly shorter bolts to the transmission end. Refit and tighten the oil pan-to-transmission bolts to the specified torque, then starting from the transmission end, tighten the oil pan-to-engine bolts in pairs to the specified torque. Complete the refitting by renewing the oil cooler-to-oil pan O-ring seals, tightening all fasteners to their specified torque, fitting a new engine oil filter, and refilling the engine with oil, with a recommendation to wait a minimum of two hours before starting the engine to allow the sealant to cure fully.