×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo 960 Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Turbocharger found

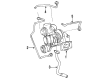

Volvo 960 Turbocharger Part Number: 8603518

$604.83 MSRP: $725.88You Save: $121.05 (17%)Ships in 1-2 Business Days

Volvo 960 Turbocharger

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Turbocharger and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo 960 parts. The prices are unbeatable, allowing you to get value for money. Each genuine 960 Turbocharger comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo 960 Turbocharger Parts and Q&A

- Q: How to properly work on the exhaust system and replace the turbocharger on Volvo 960?A:Before working on the exhaust system, soak the retaining hardware in a good rust penetrant, waiting 10-15 minutes for the penetrating solution to work. For the 2.3L 4-cylinder engine, disconnect the negative battery cable, remove the preheater hose and disconnect the pipe and rubber bellows between the air/fuel control unit and turbocharger. Pull out the crankcase ventilation hose, remove the pipe and connector between the turbocharger and intake manifold and put a cover over the turbocharger intake and outlet ports. Disconnect the exhaust pipe, remove the top and bottom heat shields, remove the brace between the turbocharger and manifold. Remove the oil pipe clamp and retaining screws, and take care not to get dirt into the oil passages, then remove the manifold retaining nuts (one of which should be left in place). Remove the oil delivery pipe, disconnect the air/fuel control unit and, together with the bottom section of the air cleaner, take it to the right wheel housing and cover to protect. Lift the assembly forward and up, remove the manifold gaskets and disconnect the return oil pipe O-ring from the cylinder block. For installation purposes, a new gasket for the Exhaust Manifold and a new O-ring for the return oil pipe (coated with oil) should be used. Install the turbocharger on the exhaust manifold making tight all bolts in certain sequence, install the assembly on engine; connect all oil pipes with new O-rings. Reinstallation of the air/fuel control unit and air cleaner, followed by the heat shields, spark plug wires, exhaust pipes, preheater assembly and expansion tank. Reconnect the negative battery cable, remove the wire from the terminal 15 of the ignition coil and crank the engine to get oil running to the turbocharger. After reattaching the coil wire, start the engine and let it idle before test driving. For the 2.3L and 2.4L 5-cylinder engines, disconnect the negative battery cable, drain the engine coolant and oil and remove the heat shield over the exhaust manifold. Move the upper air charge pipe and rubber hose out of the way, remove the upper turbo coolant return pipe and raise the vehicle to remove various components from under the vehicle. From the top, take out the exhaust pipe to turbo nuts, take off the coolant inlet pipe, take off the turbo/exhaust manifold nuts. When the turbo and old pin bolts are removed, oil the new O-rings and install them. Install new pin bolts with threadlocking compound, attach the hoses to the turbo and tighten the exhaust manifold nuts. Reconnect various hoses and pipes by reinstalling the oil pipe, exhaust pipe bracket bolt, as well as lowering the vehicle. Finally, raise the car to remove the clamp from the coolant return hose, reconnect the negative battery cable, run the engine and check boost pressure and oil and coolant levels, bearing in mind that a fault code reset may be required after replacing the turbocharger.