×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo V40 Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Turbocharger found

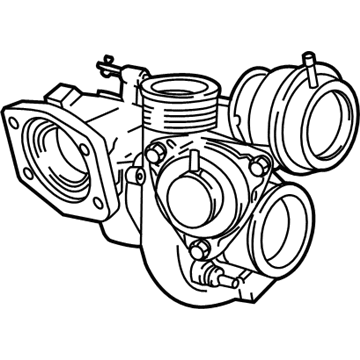

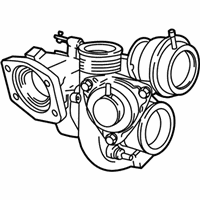

Volvo V40 Turbocharger Part Number: 8602393

$604.83 MSRP: $725.88You Save: $121.05 (17%)Ships in 1-2 Business Days

Volvo V40 Turbocharger

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Turbocharger and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V40 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V40 Turbocharger comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V40 Turbocharger Parts and Q&A

- Q: What is the role of a water-cooled turbocharger in enhancing engine efficiency on Volvo V40?A:A water-cooled turbocharger is used in all turbo models, improves the efficiency of the engine by raising the pressure in the inlet manifold above the atmospheric level and literally pushes the air/fuel mixture into the cylinders instead of simply drawing it in. The turbocharger works from the energy contained in the exhaust gas, which can cause a turbine wheel connected to a shaft to spin, which in turn spins a compressor wheel, compressing the intake air prior to its arrival on the inlet manifold. After passing through the turbocharger, the compressed air is cooled in an intercooler which decreases the volume, allowing more air to enter the combustion chambers which increases engine efficiency and also minimises the risk of detonation. Boost pressure in the inlet manifold is controlled by a wastegate which diverts exhaust gas according to signals from a pressure sensitive actuator that is controlled by the turbocharger control valve associated with the electronic control unit of the fuel system. There is a turbo shaft lubricated under pressure from the oil gallery of the engine, floating on a cushion of oil with a return pipe from the sump. Water cooling - to maintain cooler operating temperatures for the turbo bearings, coolant is circulated even after the engine is stopped to cool the turbocharger Precautions are very necessary because of the high speed and temperature at which the turbocharger operates; you need not expose the ports to air, avoid racing the engine immediately after starting, let the engine return to its idle position before turning off, idle it after high speed runs, and service it according to recommended intervals for oil and filter changes to use quality oil to avoid carbon buildup and possible failure.