×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo V40 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Discs found

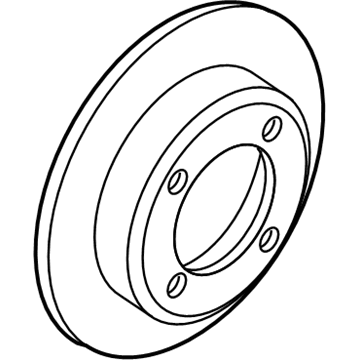

Volvo V40 Rotor Part Number: 30872940

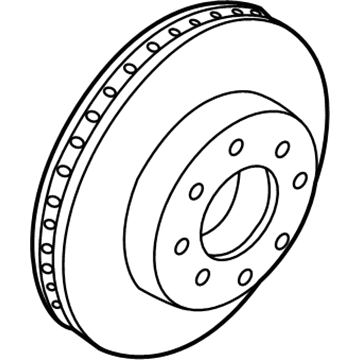

$37.88 MSRP: $64.69You Save: $26.81 (42%)Ships in 1-2 Business DaysVolvo V40 Rotor Part Number: 30818027

$63.32 MSRP: $109.03You Save: $45.71 (42%)Ships in 1-2 Business Days

Volvo V40 Brake Disc

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Brake Disc and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V40 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V40 Brake Disc comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V40 Brake Disc Parts and Q&A

- Q: How to inspect and replace brake discs on Volvo V40?A:To check the front or rear brake discs, engage the handbrake and undo the relevant wheel nuts then jack the car up and rest it on axle stands. Remove the appropriate roadwheel and slowly rotate the brake disc to observe both sides, if required remove the brake pads for easier access. Light scoring is the norm in the area swept by the pads, but heavy scoring or cracks are a sign of needing disc replacement. A rust and brake dust lip around the periphery of the disc is normal and is free to scrape off, but if too much wear has occurred and the lip is formed, measure the thickness of the disc with a micrometer at various points, if it is at or below the minimum thickness, it must be changed. To check for warping, the disc is fixed to the hub and run-out is measured by dial gauge or feeler blades; if measurements are greater than the maximum limit then a disc replacement is required but then ensure that the hub bearing is in good condition first. Examine the disc for cracks and other damage, replacing if necessary. For removing, slide out the retaining clip and free the caliper brake hose, then remove the bolts holding the caliper bracket and slide the caliper assembly off the disc, tying it to the coil spring so as not to put a strain on the hydraulic hose. If the disc is to be refitted mark the position of the disc in relation to the hub then remove the retaining screw and the disc, tapping lightly if stuck. Refitting has the steps of reversing removal steps clean and flat mating surfaces alignment of marks made during remove wiping any preservative of new disc positioning caliper with pads on either side of disc tightening new mounting bolts to specified torque refitting roadwheel lower car tighten wheel nuts apply footbrake several times to check good pad contact with disc.