×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

Genuine Volvo V40 Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Brake Calipers found

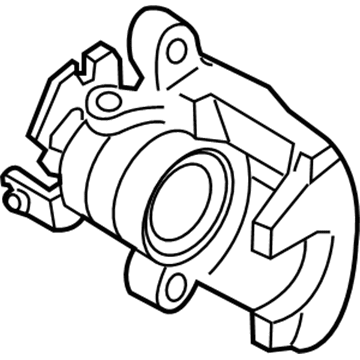

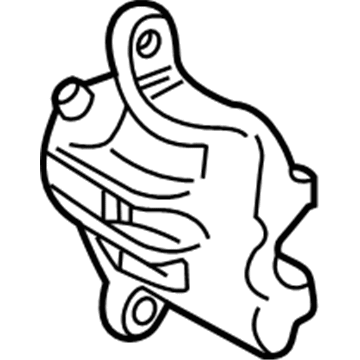

Volvo V40 Caliper, Driver Side Part Number: 8251698

$255.04 MSRP: $301.11You Save: $46.07 (16%)Ships in 1-2 Business DaysVolvo V40 Caliper, Passenger Side Part Number: 8251699

$255.04 MSRP: $301.11You Save: $46.07 (16%)Ships in 1-2 Business DaysVolvo V40 Caliper, Driver Side Part Number: 8251696

$208.74 MSRP: $246.00You Save: $37.26 (16%)Ships in 1-2 Business DaysVolvo V40 Caliper, Passenger Side Part Number: 8251697

$208.74 MSRP: $246.00You Save: $37.26 (16%)Ships in 1-2 Business DaysVolvo V40 Caliper, Driver Side Part Number: 8251694

$220.03 MSRP: $259.44You Save: $39.41 (16%)Ships in 1-2 Business DaysVolvo V40 Caliper, Passenger Side Part Number: 8251695

$220.03 MSRP: $259.44You Save: $39.41 (16%)Ships in 1-2 Business Days

Volvo V40 Brake Caliper

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Brake Caliper and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V40 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V40 Brake Caliper comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V40 Brake Caliper Parts and Q&A

- Q: How to remove and overhaul the front brake caliper on Volvo V40?A:To remove the front brake caliper, first be sure to apply the handbrake, and to loosen the front wheel nuts, first jack up the front of the car and place it on axle stands, before removing the relevant front roadwheel. Minimise losses of fluid by taking the master cylinder reservoir cap off and sealing it with polythene or brake hose clamp. Clean around the brake hose union on the caliper and slacken and remove the bolt, collecting the sealing washers and plugging the end of the hose to avoid fluid loss and entry of dirt. Remove the old sealing washers and clean spilled fluid with cold water. Next slacken and remove the upper and lower caliper guide pin bolts and lift the caliper away from the Brake Disc and remove the caliper from the car leaving the brake pads in position. For the overhaul, wipe away dust and dirt from the caliper, withdraw the partially-ejected piston and remove the dust seal. Extract the piston hydraulic seal carefully, and then clean all the parts with suitable cleaning mediums without the use of mineral-based solvents. Check all components for signs of wear or damage and renew any components that are not in good condition, particularly the cylinder bore and piston. If the assembly is suitable for re-use, get a repair kit and replace all rubber seals. On reassembly, make sure all parts are clean and dry, soak the piston and new piston seal in clean hydraulic fluid and install the new piston seal with fingers only. Fit the new dust seal and gently ease the piston in the cylinder bore. If renewing guide pins, lubricate the pin shafts and fit the gaiters, and put the pins in the caliper bracket. Before refitting, fill caliper with fresh hydraulic fluid by slackening the bleed screw and pumping until bubble free fluid comes out. Make sure the brake pads are fitted properly, press the caliper to position, press down and tighten the bolts of the guide pins according to the required torque. Install new sealing washers on both sides of the brake hose union, screw the brake hose union bolt in place, and tighten to the stated torque. Finally, remove any clamps or polythene, bleed the hydraulic system, refit the roadwheel, lower down the car and tighten the roadwheel nuts to the specified torque.

- Q: How to replace the rear brake caliper and ensure proper reassembly on Volvo V40?A:Chock the front wheels, loosen the rear wheel nuts and then jack the rear of the car up and put it on axle stands before removing the relevant rear wheel. Release the handbrake lever and back off the handbrake cable adjuster to get the maximum freeplay in the cables. Free the handbrake cable from the caliper lever and unclip the outer cable from the body of the caliper. Minimise any loss of fluid by first removing the master cylinder reservoir cap, and tightening it down on a piece of polythene for an air tight seal, or you may apply a brake hose clamp or similar to clamp the flexible hose. Clean the area around the brake hose union on the caliper, slacken and remove the bolt, recovering the sealing washers fitted on each side of the hose union. Plug the hose end to minimise the loss of fluid and prevent dirt entering, disposing of the sealing washers and ensuring that new ones are used on refitting. Wash off any spilt fluids immediately with cold water. Slacken and remove the upper and lower caliper guide pin bolts with a slim open-ended spanner to stop the guide pin rotating and now lift the caliper away from the Brake Disc and remove it from the car leaving the brake pads in place in the caliper mounting bracket. Discard the bolts and make sure new ones are used on refitting. With the caliper on the bench, clean all traces of dust and dirt without inhaling the dust. Remove the piston from the caliper bore by rotating it anti-clockwise with the help of suitable circlip pliers engaged in the caliper piston slots, and then removing the piston by hand after it turns freely. Remove the dust seal from the piston and gently extract the piston hydraulic seal from the caliper bore with a small screwdriver, making sure not to mark the bore. Withdraw the guide pins from the caliper mounting bracket and remove the guide sleeve gaiters, checking out all the caliper components, renewing them as needed and keeping in mind that the handbrake mechanism must not be dismantled. On reassembly, make sure that all parts are clean and dry, dip the piston and new piston seal in clean hydraulic fluid, and slime clean fluid on the cylinder bore surface. Fit the new piston seal with only the fingers to manipulate it into the cylinder bore groove, then the new dust seal to the rear of the piston and fit the outer lip of the new dust seal into the caliper body groove. Carefully squaringly ease the piston into the cylinder bore using a twisting motion, turning it clockwise, all the way back, then seat the inner lip of the dust seal in the piston groove. Apply silicone grease or a copper-based brake grease to the guide pins and fit new gaiters to the guide pins and fit the pins to the caliper mounting bracket and ensure that the gaiters are correctly located. Prior to refitting, fill the caliper with fresh hydraulic fluid by slackening the bleed screw and pumping the fluid through the caliper until bubble-free fluid is expelled from the union hole. Make sure the brake pads have been correctly fitted into the caliper mounting bracket, then move the caliper to fit the housing over the pads, making sure the pad anti-rattle springs are correctly fitted in the caliper body. On the caliper, press down and insert the new guide pin bolts and tighten them according to the torque specified in the manual, holding the guide pin there with an open-ended spanner. Position a new sealing washer on both sides of the brake hose union and screw in the hose union bolt, making sure to adjust the hose end fitting into proper position before applying the brake hose union bolt to the correct torque. Remove the brake hose clamp or polythene and bleed the hydraulic system noting that if precautions were taken to minimise brake fluid loss it should only be necessary to bleed the relevant rear brake. Reconnect the handbrake cable securely to the caliper and adjust, refit the roadwheel, lower the car to the ground and tighten the roadwheel nuts to the specified torque.