×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

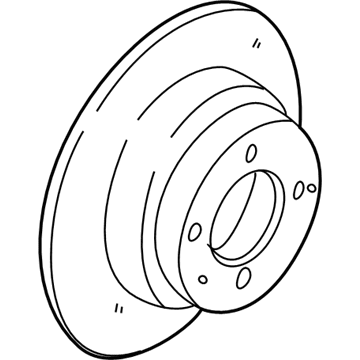

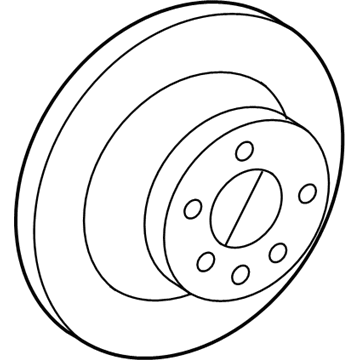

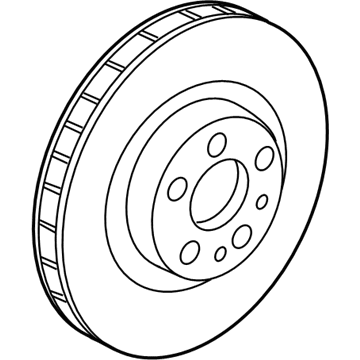

Genuine Volvo V70 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Brake Discs found

Volvo V70 Rotor Part Number: 31262099

$53.07 MSRP: $90.63You Save: $37.56 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31471746

$58.07 MSRP: $99.16You Save: $41.09 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31471821

$64.07 MSRP: $110.32You Save: $46.25 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31471830

$67.65 MSRP: $116.47You Save: $48.82 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31262092

$67.92 MSRP: $116.93You Save: $49.01 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31471827

$78.26 MSRP: $134.76You Save: $56.50 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 30645223

$79.09 MSRP: $136.16You Save: $57.07 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor, Front Part Number: 31341382

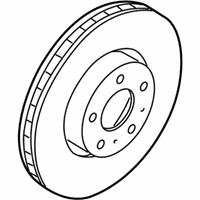

$80.30 MSRP: $138.26You Save: $57.96 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31262095

$86.53 MSRP: $102.16You Save: $15.63 (16%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31471028

$88.43 MSRP: $152.25You Save: $63.82 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor, Front Part Number: 30645222

$94.82 MSRP: $163.24You Save: $68.42 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31499996

$96.53 MSRP: $166.21You Save: $69.68 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor, Front Part Number: 31400764

$99.96 MSRP: $172.10You Save: $72.14 (42%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31262094

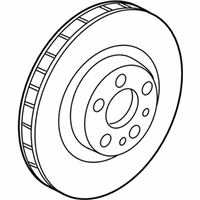

$77.43 MSRP: $91.41You Save: $13.98 (16%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 9475266

$159.41 MSRP: $188.20You Save: $28.79 (16%)Ships in 1-2 Business DaysVolvo V70 Rotor Part Number: 31262097

$77.43 MSRP: $91.41You Save: $13.98 (16%)Ships in 1-2 Business Days

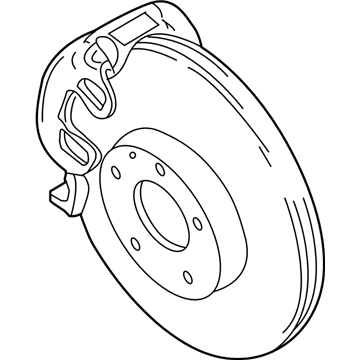

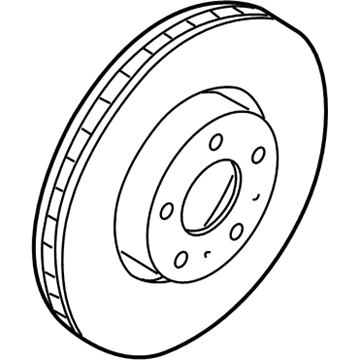

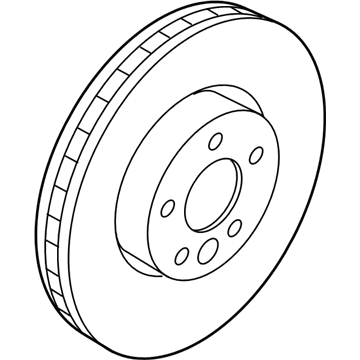

Volvo V70 Brake Disc

OEM parts are the only choice for top quality and real functionality. They pass strict checks, and they match Volvo's factory specs, so installation is easy. If you need new Brake Disc and you want quality and fit. You will find both here. Our site has a wide range of OEM Volvo V70 parts. The prices are unbeatable, allowing you to get value for money. Each genuine V70 Brake Disc comes with the manufacturer's warranty. That gives you peace of mind. We ship fast to your door. Order today, and enjoy a smooth, no-hassle upgrade with parts that fit right.

Volvo V70 Brake Disc Parts and Q&A

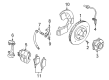

- Q: What should you be aware of before starting work on rear Brake Disc maintenance on Volvo V70?A:Before beginning work, know about the dangers of asbestos dust. If one of the rear brake discs has to be renewed, both of them should be renewed at the same time in order to ensure even and consistent braking, and new brake pads should be installed at the same time. With the rear brake pads removed the inspection procedures are the same as the front brake disc, checking the condition of the handbrake drums after removal. Refinishing, run-out and out-of-round are specified and the drums are unlikely to wear unless the handbrake is habitually used to stop the car. If not already done, remove the rear brake pads and support this brake caliper or suspend it with string or wire tied to a convenient suspension component. Undo the two mounting bracket bolts on the caliper and remove the mounting bracket bearing in mind that new bolts will be needed to refit the caliper. Unscrew the disc retaining bolt, mark the position of the disc in relation to the hub and pull off the disc, tapping it with a soft-faced mallet if needed. If the disc is binding on the handbrake shoes, then inside the car, prise out the centre console trim panel next to the handbrake lever and slacken the adjuster nut at the back of the handbrake lever until you get some slack in the handbrake cables. Make sure that the hub and disc mating faces are spotlessly clean and clean any rustproofing compound off a new disc using degreaser and a rag. Locate the disc on the hub with the orientation marks facing and refit the retaining bolt. Fit the brake caliper mounting bracket and tighten the new bolts to the specified torque, refit the brake pads and adjust the handbrake.

- Q: What should you be aware of before starting work on front brake disc renewal and inspection on Volvo V70?A:Before you begin work know the dangers of asbestos dust. If one of the discs requires renewal, both should be renewed at the same time to ensure that the braking is even and consistent, and new brake pads should also be fitted. Starting with the front brake pads, remove and check for cracks or deep scoring on the disc friction surfaces, light grooving is normal and can be ignored. A cracked disc must be replaced while a scored disc can be reclaimed by machining if the thickness is still above the specified minimum. Check the disc run out by a dial test indicator placed near the outer edge, if the run out values are higher than the figures stated then machining may be possible, otherwise a renewal is required. Excessive variation in disc thickness can be a source of judder, so take the thickness of the disc using a micrometer. After removing the brake pads and caliper, undo the two mounting bolts to remove the brake caliper bracket and limiter bracket with the note that new bolts will be required for refitting. Check whether the location of the disc in relation to the hub is marked; if not, make your own mark for refitting. Remove the bolt that holds the disc to the hub and remove the disc. With a new disc, ensure that the hub and disc mating faces are clean and remove any rustproofing compound with degreaser and a rag. Align the disc on the hub with the orientation marks and re-fit the retaining bolt and tighten it. Reattach the brake caliper bracket and limiter bracket, tightening the new bolts to specified torque, and then finally refit the brake pads.