×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volvo Parts

My Garage

My Account

Cart

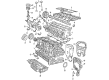

Genuine 2006 Volvo S80 Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Pistons found

2006 Volvo S80 Piston Part Number: 30731508

$191.48 MSRP: $247.40You Save: $55.92 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Kit; Piston

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30731508

- Warranty: This genuine part is guaranteed by Volvo's factory warranty.

2006 Volvo S80 Piston Part Number: 30731509

$182.64 MSRP: $237.81You Save: $55.17 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Kit; Piston

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30731509

- Warranty: This genuine part is guaranteed by Volvo's factory warranty.

2006 Volvo S80 Piston Part Number: 30731510

$201.06 MSRP: $259.77You Save: $58.71 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Kit; Piston

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30731510

- Warranty: This genuine part is guaranteed by Volvo's factory warranty.

2006 Volvo S80 Piston Parts and Q&A

- Q: How to remove the cylinder head, oil pump, and flywheel/driveplate while ensuring proper reassembly and inspection of the pistons and connecting rods on 2006 Volvo S80?A: To remove the cylinder head, oil pump and flywheel/driveplate you need to start by removing the sump. Check for a well worn area at the inside of the top of the bores, if present, may need removal before piston extraction, although if any real damage is likely to be present, rebore and new pistons/rings will need to be done. Make sure each connecting rod and cap has marks under which they can be identified and if necessary, paint or punch suitable marks for proper reassembly. Remove connecting rod bolts, tap the cap with a soft hammer to release it, and remove the cap and lower bearing shell (note that new bolts & shells are needed for reassembly). Push connecting rod and piston out of bore, recover loose bearing shell (if any). Refit the cap correctly ensuring parts are not mixed up, ensuring that any fractured surfaces are not damaged in the process. Check for the presence of an arrow on the top of the piston pointing to the timing belt end, if not, put a mark on a direction. Clean the piston/connecting rod assemblies before inspection, carefully removing the original piston rings so as not to scratch them. Scrape carbon off the top of the piston and in the ring grooves, using an old ring to get carbon off the grooves without damaging them. After cleaning, inspect for excessive wear or damage, if the pistons and cylinder bores are satisfactory, original pistons can be re-used with new rings. Inspect each piston for cracks, scoring or burned areas, and investigate any problems in order to prevent recurrence. Examine connecting rods for damage and make sure connecting rods are not bent and separate pistons and connecting rods if necessary by removing circlips and pushing out gudgeon pin. If any piston is wore, all of these would have to be replaced and if rebore was done previously, oversized pistons may be necessary. Measure ring to groove clearance and check gudgeon pin fit, if play is noticeable, new bushings or oversize pins are needed. Assemble any new parts required, oil the gudgeon pin, reassemble the connecting rod and piston in the correct way and lock the gudgeon pin in with the circlip so that the opening is pointing downwards. Repeat for the rest of the pistons.